|

|

|

|

|

|

|

|

| Seacon's Quality Management |

|

|

Quality is one of the cornerstone on which Seacon is built. Finished products are approved for packing only after they pass two levels of stringent quality checks. Raw materials are properly sampled and defects detected to ensure compliance of quality standards before being inducted into the production process.

We conduct regular meetings between our suppliers, purchase and production team to identify, analyze and set standard operating procedures to proactively curb any prospective defects in our production process.

|

|

Resource Management

We have well trained and motivated employees. They receive the necessary training in order to be able to carry out their tasks with utmost quality and efficiency.

|

|

|

We have invested a sizeable capital just to make sure that our products meet and exceed all expectations on quality and durabilty issues. Please have a look at few of our quality control measures we adopt. |

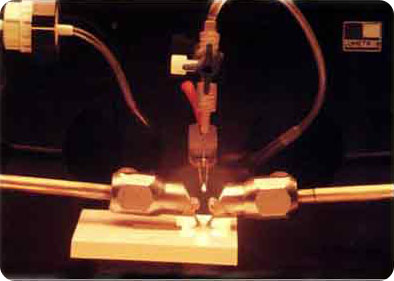

The Glow Wire Test:

The product is subjected to 850 Degrees Celsius and the fire retardent capability of the product is verified.

|

|

The tracking index test:

The product is sujected to 50 drops of 0.1% Ammonium Chloride to confirm and verified that the body of our products are non-conductive in nature.

|

|

The On-Off Endurance test:

The product is sujected to 30,000 On-Off operations cycles at heavy load. This is done to make sure that our switches are able to with stand all kind of stress and have long durability.

|

|

|